How I got in to making bows

In 2011 I was finding difficult to shoot my Chris Boyton longbow and though it was just me. It became apparent it wasn’t. I wasn’t shooting as often as I used to and the bow had become too heavy for me. I asked Chris to take it down in draw weight for me. He did this for me in September 2011, going from a 58lb to 46lb draw weight. It did wonders to my shooting and I felt much more comfortable. Chris’s comment “I should show you how to do this” got me thinking I could do it myself. So every now and then over next couple years I asked Chris about showing me and teaching me how to make a bow.

At the end of 2013 I finally persuaded Chris Boyton to teach me how to make a longbow; a date was fixed at the beginning of December.

Chris showed me step by step what to do to shape a longbow stave. He was very surprised that I could just pick up the tools and be able to use them! I said to him it’s something to do with being a carpenter’s son, being around wood working tools most of my life and making things with scraps of wood when I was a kid. After the two solid days with Chris I left the bow with him to varnish and fit the braided handle. I could have done it myself but I wanted Chris’s finishing touches.

A few months after making the bow with Chris we managed to catch up at Carol’s workshop and we chatted more about making bows. We spent many hours discussing different bows and how they were made. A lot of the detail was going over my head but I was trying to take it all in as found it fascinating. We didn’t always talk archery; we did talk a lot about how things are engineered especially with regard to my work and what Chris used to do. It was always good to talk with Chris; the conversations were wide and varied.

In the middle of 2016 I decided it was time to put the skills I had learned from Chris in practice and I started making bows. I managed to get hold of a longbow stave that Paul Reed had made and started shaping it in to a bow. I went a little bit too hard on the roughly shaping and thought I had wrecked the stave while trying to turn it into something resembling a bow. I stepped back decided to have a break from working on the bow stave. Over next couple weeks Chris popped into Carol’s workshop and he gave me great advice on how the rescue the bow. The poundage of the bow wouldn’t be as high as I originally thought. Also the draw length wasn’t going to be anywhere close to 28 inches as I originally planned. I managed to rescue it with Chris’s help and input. This bow was numbered No. 002, as my number 001 will always be the bow I made with Chris.

In the middle of 2016 I decided it was time to put the skills I had learned from Chris in practice and I started making bows. I managed to get hold of a longbow stave that Paul Reed had made and started shaping it in to a bow. I went a little bit too hard on the roughly shaping and thought I had wrecked the stave while trying to turn it into something resembling a bow. I stepped back decided to have a break from working on the bow stave. Over next couple weeks Chris popped into Carol’s workshop and he gave me great advice on how the rescue the bow. The poundage of the bow wouldn’t be as high as I originally thought. Also the draw length wasn’t going to be anywhere close to 28 inches as I originally planned. I managed to rescue it with Chris’s help and input. This bow was numbered No. 002, as my number 001 will always be the bow I made with Chris.

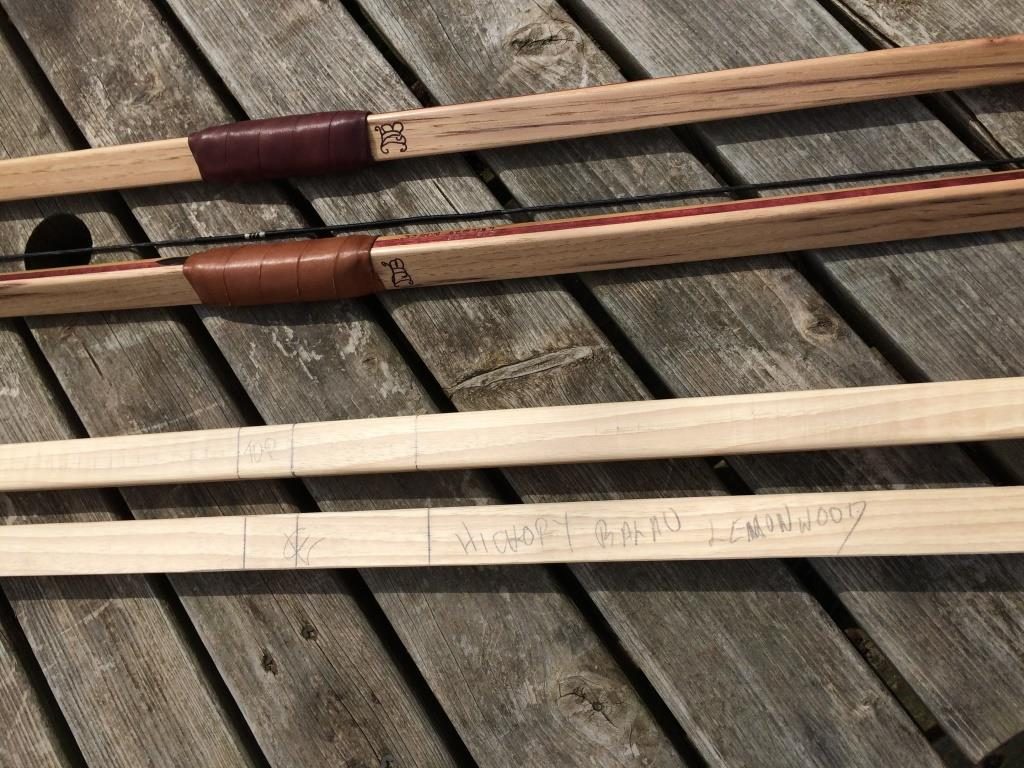

Over the next 14 months I made 2 more bows with Chris’ tips and advice. I also got advice and help from Paul Reed. It was great having two great bowers give me so much help and advice, I just had to take it all in. The best praise I received was when Chris said to me “Darren these 2 bows are well made and finished. You are doing better than I ever did when I first started. Especially as these are really only your 3rd & 4th bows.” This struck a chord with me and inspired me on to make more bows!

At the end of 2017 I started on another stave and managed to finish it in 3 months which was quite quick in comparison to my previous bows. This wasn’t too bad as I’d only been working on the bows at weekends. I struggled with making the horn tips but at the end they finished the bow off nicely. Chris again gave me pointers but not as many. As he said, I have to learn from my own mistakes and step back every now and then to make sure I can get better perspective to achieve high quality workmanship. When I finished the bow I hung it up in Carol’s workshop to get Chris’ feedback as I knew he was coming in during the week. When Chris came in I was told that he was really impressed and said I’d come a long way. This bow became No. 005 and was the last bow Chris gave me advice on. It will always be a special bow.

At the end of 2017 I started on another stave and managed to finish it in 3 months which was quite quick in comparison to my previous bows. This wasn’t too bad as I’d only been working on the bows at weekends. I struggled with making the horn tips but at the end they finished the bow off nicely. Chris again gave me pointers but not as many. As he said, I have to learn from my own mistakes and step back every now and then to make sure I can get better perspective to achieve high quality workmanship. When I finished the bow I hung it up in Carol’s workshop to get Chris’ feedback as I knew he was coming in during the week. When Chris came in I was told that he was really impressed and said I’d come a long way. This bow became No. 005 and was the last bow Chris gave me advice on. It will always be a special bow.

At the beginning of 2017 I discussed with Chris about having another bow making course with him to refine my skills and to make a bow for my girlfriend (now my wonderful wife) so she could have a Boyton bow. Due to Chris’s commitments this kept being put off, which I understood. We spoke again at the end of 2017 and Chris said next year. At the beginning of 2018 we finally agreed a date in September!

I couldn’t wait! I was sworn to secrecy until we started but over the next few months we talked about Chris passing on his knowledge for both bow and arrow shaft making. The month of September 2018 was going to be huge for me. During these discussions Chris gave glimpses of how he made the arrow shaft. He jokingly said “You will have to wait until September to learn more”.

With Chris’s cancer diagnosis this never came to fruition and he sadly lost his battle. I miss Chris and the laughs we had. He was a great source of advice on bow making, engineering and most of all the stories he told.

Since making bow No.005 I’ve worked on a few bows for archery friends, from re-working / shaping, reducing in weight to repair work. To learn more and to try to continue on what Chris had shown & taught me.

Chris has inspired me to make bows of the highest quality I can and to continue on the legacy he taught me.

I would also like to say thank you to Paul Reed for supply me with the bow staves and the bits advice he gave me along the way. Also I would like to thank Carol Edwards-Pearce for all the encouragement while making the bows.